Security solutions to help the manufacturing sector function are available in the market, but that doesn’t mean the challenges ahead of customers and vendors are all sorted. One of the biggest challenges that remain is how to get people back into the building and then once there, how to provide a safer, more secure, and efficient environment.

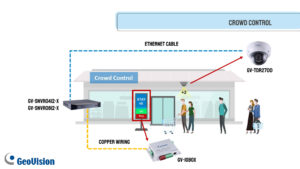

Step one of the process is typically performing an initial temperature screening upon arrival and entry, but it’s important for the process to remain efficient, with minimal interruption to an employee’s normal routine. Companies can automate the temperature screening process to allow for 20-30 people per minute to enter one entrance safely. Next, it’s important to look at how to maintain the current recommendations of social distancing and PPE compliance within the building.

Factories usually need to integrate with the access control system, the fire linkage system, the central control display of various equipment, and the query and recall of events. Integrating such different solutions to work together seamlessly remains a significant challenge for the industry.

COVID restrictions in manufacturing plants

Access to the sites is another major barrier as many manufacturing plants have made it difficult for people to enter and exit the sites, to limit risks. While restrictions are necessary, it does make installations difficult.

Complying with the restrictions associated with minimum numbers of people on-site, while implementing and testing new solutions and technologies with the integrators is challenging. Remote access to equipment – such as intelligent cameras – allows configuration and fine-tuning to be done off-site. However, progress towards a higher level of digitalization is being constrained by budget cuts. Many companies are putting developments on hold, which means that adoptions of new solutions to overcome challenges are slowing down.

Challenges beyond technology

Interestingly, so much of the challenge is not around the technology, but how to leverage advanced intelligence and technology to find creative ways to solve the problems these facilities face. There may be privacy or operational concerns that must be navigated as solutions are implemented. For example, an organization may not want their canning machine networked for fear of a breach. There may even be concerns that investing in a COVID-19 solution may not be worth it as it may become useless once a vaccine is found.

So, it becomes integral for both manufacturers and integrators to incorporate each client’s concerns and evaluate challenges to customize their approach. There’s no cookie-cutter, one-size-fits-all solution that will address each facility’s needs. The rise in COVID-19 cases or outbreaks in more of these ‘essential’ businesses (like manufacturing or food processing) means that this becomes even more crucial, as the operational procedures differ from facility to facility — and can even differ within a single facility and operating environment.

To sum up, a combination of movement restrictions and the need to think out of the box with available solutions could be the two major challenges that the security industry faces in the manufacturing sector. Unfortunately, COVID-19 has given the world very little time to think things through. But since the pandemic may not be over anytime soon, the industry must continue efforts to get the right combination of security solutions in place to help manufacturing businesses survive.

Adapted from a&s Magazine